Automatic Disposable syringe assembly machine

Automatic Assembly Machine for Syringe is a kind of medical equipment, which is specially designed for Medical Equipment Industry. And the whole process is automatically completed. Operating panel with touch screen, counting finished products, easy to operate with high efficiency, and running stably with lowest noise. It can meets the demand of all kinds of plants.

The production efficiency is high,the operation simple is convenient,

compared with the manual production greatly reduces operator's labor

intensity

The production line area is small

In the production process avoided the operator and the needle point

contact, prevented the needle point two pollution

The performance is stable; The functional element,the control system

uses imports the part.

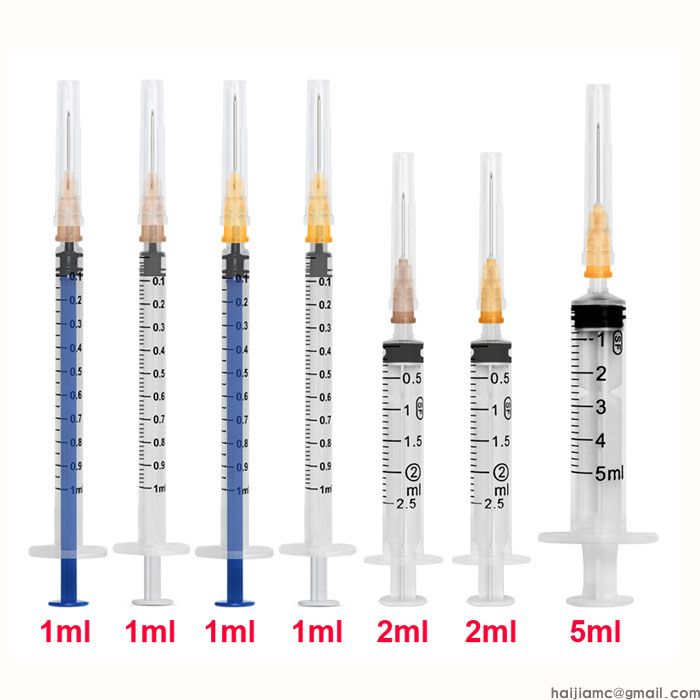

Production SPEC | 1ml | 2-3ml | 5ml | 10ml | 20ml | 30ml | 50ml |

Production speed | 180pcs/min | 200pcs/min | 250pcs/min | 250pcs/min | 160pcs/min | 150pcs/min | 120/min |

Dimension | 4200×3000×2200 | ||||||

Weight | 1500kg | 1500kg | 1500kg | 1500kg | 1500kg | 1500kg | 1500kg |

Power supply &Power | AC220v/ 2.5KW | ||||||

Compressed air flow | 0.3m3/min | 0.3m3/min | 0.3m3/min | 0.3m3/min | 0.3m3/min | 0.3m3/min | 0.3m3/min |

description of disposable syringe products

Disposable syringes are made of high molecular polypropylene materials and have good biocompatibility. They are divided into three-piece and two-piece structures. The three-piece structure consists of a core rod, a rubber stopper, outer sleeves and an injection needle and outer packaging.

The two-piece structure is composed of a core rod, a outer sleeves, an injection needle, and an outer package. Medical needles and syringes should be sterilized with ethylene oxide. Sterile, no heat source. Syringe packaging is plastic bag packaging or paper-plastic packaging.

The name, the standard of the product, the specification model, the batch number, whether it is with a needle, the production date, whether it is sterilized with ethylene oxide, the sterilization period is valid, note Matters, manufacturer and manufacturer information must be indicated on the packaging.

Qualified products should have high transparency, clear and accurate graduation marks, and are not easy to fall off. The sliding performance should be good. The end of the tube structure should be designed with an anti-drop structure to prevent the mandrel from exiting the barrel; the core rod should be designed with a self-destructive structure to facilitate Harmless treatment after single use.

Based on the above, the production standards for disposable syringes and the production environment are all demanding. It requires the guidance of experienced personnel and the production of equipment that has undergone a large number of market inspections to meet the production requirements.

Brief description of the syringe production process

The complete production process of the syringe includes five steps including injection molding of effective assembly parts, printing of tube structure scale lines, assembly of each part to the finished product, packaging of a single finished product, and overall product sterilization (including the large investment in production of rubber plugs and needle tips. Generally outsourced directly.

If the production scale becomes larger, you can further purchase equipment for independent production), involving dozens of different machines and equipment, all links are interlocked, need to be effectively organized and arranged, The specification and size of the machine should be reasonably configured so as to achieve the most optimized capacity design with less equipment investment.

Based on decades of production experience, we integrate hundreds of on-site design solutions from domestic and overseas customers, and design customized production solutions according to the special needs of customers to achieve the purpose of optimizing production efficiency and helping customers to carry out stable production activities. Winning the market. At present, the top ten domestic syringe manufacturers (including two listed companies) and more than 80% of the syringe manufacturers all use the equipment provided by our company. The products are exported to more than a dozen countries and regions. The foreign equipment has been operating normally for more than 10 years.

Our target is to help our customer to set up a syringe plant with effective production ability in a low

cost, to produce the high quality products, and finally to benefit the local people who can get those

high quality products with low cost.