What Does This Syringe Needle Making Machine Produce?

Stainless steel needle tube forming

Needle grinding and bevel shaping

Surface polishing and inspection

(If applicable) automatic handling

Syringe Needle Manufacturing Process

The manufacturing of medical syringe needles is a highly precise and controlled process, requiring specialized machinery to ensure dimensional accuracy, surface quality, and compliance with medical standards. A typical syringe needle manufacturing process includes the following steps:

1. Stainless Steel Tube Preparationed

Medical-grade stainless steel tubes are used as raw material. The tubes are carefully inspected for diameter consistency, wall thickness, and surface defects before entering the production line.

2. Needle Drawing and Straightening

The stainless steel tubes are drawn to the required diameter through precision drawing processes. After drawing, straightening is performed to ensure the needle tube maintains strict linearity, which is essential for subsequent grinding and assemblyy.

3. Needle Grinding and Beveling

The needle tip is formedd through high-precision grinding. This step defines the bevel angle, sharpness, and penetration performance of the needle. Multi-facet grinding can be applied depending on medical application requirements.

4. Surface Polishing and Finishing

After grinding, the needle undergoes surface polishing to remove micro-burrs and improve smoothness. This process reduces insertion resistance and enhances patient comfort while meeting medical surface quality standards.

5. Inspection and Quality Control

Finished needles are inspected for dimensions, tip geometry, surface finish, and consistency. Optical inspection and precision measurement systems are commonly used to ensure each needle meets medical-grade specificationsed.

This controlled manufacturing process ensures that syringe needles achieve the required sharpness, strength, and reliability for medical use, and that the final products are suitable for further assembly into disposable syringes or medical devices.

Syringe assembly machine syringe needle making machine

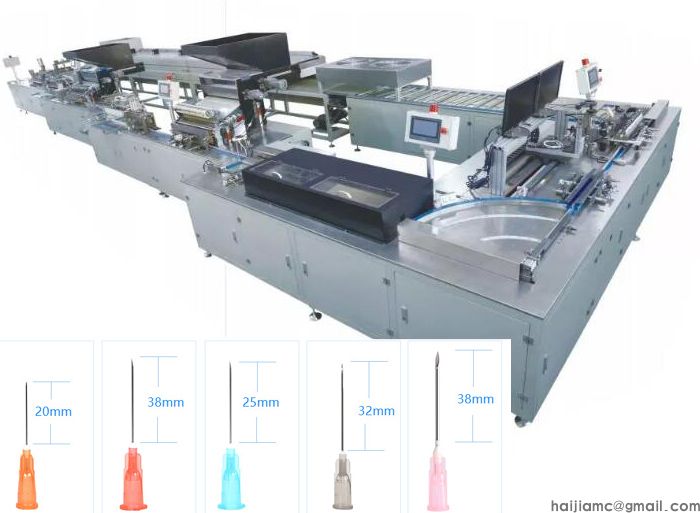

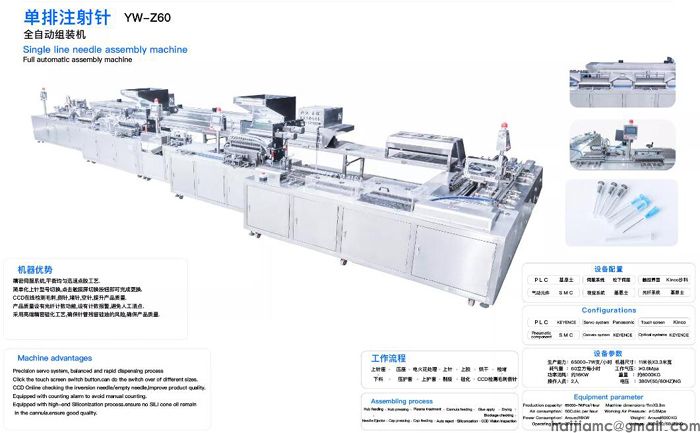

Automatic Hypodermic Needle Assembly Machine

1、Configuration of the machine: Japan Omron programmable controllers, touch screen control system, servo motor mechanism Tim glue, glue stationary process,the detection system used in Japan Keyence CCD image aerodynamic configuration using imported components.

1Needle hub loadin—>2 pressing needle hub— 3assembly of cannula —4 gluing (epoxy resin glue) —5 curing in oven fixture cooling —> 6 detection of blockage— 7 CCD detection of burr and inverted cannula —> 8 silicification — 9 unqualified extraction —> 10 cap loading— 11* pressing cap —> 12 unloading Assembly

4、 Resistant nylon strip shall be provided at all the places where the equipment fixtures contacts the table surface to reduce the powder and foreign matters etc.when friction.

5、:Capicity: 24G, 23G, 22G, 21G 68,000pcs per hour;26G,25G, 18G, 16G 50,000 pcs per hour.

6、 Machine need 2 operators

Production Video:

Plastic syringe assembly machine equipment:

Syringe manufacturing working step by step:

A.Plastic Plunger,barrel,needled and cap injection moulding.

B.Barrel scale line printing

C.Syringe assembly

D.Individual syringe Packaging

E.Cartonning

F.EO sterilization

Our solution advantages:

1.Save your time:we offer turn-key solutions,we offer machine,machine commission and training.help you started your project.

2.Safe:Our machines are equipped with protective cover, when the machine is running, the cover is closed, when the cover is open, the machine will stop running, which prevent worker from injury and also there will be no dust pollution to pollute syringe in process.

2.Stable running:Our machine can keep stable running 24 hours per day. So you can make the production shifts according to your demand. If later even you run it 24 hours still not enough for your demand, cause you get more and more orders, welcome to come to us for the second line or the third line.

3.Save labor cost: It is fully automatic controlled by PLC. The machines are connected together. Not separate ones. It can do printing, assembling in one connected line. No need labors to do the transfer when printing is finished. Finished printing product will be transfered to assemabling machine automaticlly.

4.Save materials. Our machines have high qualified rate. It is more than 99.9%. There will be almost no waste for you. More qualified product, more profit.

5.Save your production csot: We know the best supplier of plastic raw material,printing ink,film,syringe needles. get the correct supplier ,you can save much cost.

If you want to be one syringe making machine manufacturers,we are the correct supplier for you. The disposable syringe manufacturing machine price which we offer you is very reasonable.

Case show:

|  |  |

|  |  |

Q1: Are you factory or trading company?

A: We are factory located in Ningbo, Zhejiang Province with convenient transportation , prosperous economy and trade.Welcome to your visit.

Q2: How to get a target quotation for my product?

A: Please let us know the detail product spec (including type, size, structure etc), production capacity requirement etc.

Q3: Please clarify the whole business process .

A: 1) Quotation confirmed and PI/Contract signed

2) Deposit and syringe samples arranged

3) Production arranged after getting deposit and confirmation of samples and drawings

4) Trial running/test running at our site before the shipment. The result will be confirmed by the clients on site or online,or by the third party.

5) Balance payment arranged and shipment arranged

6) Installation technical support and operator training through internet

Q4: Are your engineers available for overseas service?

Q5: How to make sure the machine quality after placing the order?

A: Our product quality is with high reputation among all our clients based on our decades experience.

1) Machine trial running/test running at our site,you can come and do the on-site check or ask someone you trust to do that if you

can not arrive.We will also offer some pictures and videos and finished product samples to you for more reference.

2) Filed installation and operator training is also available when the epidemic is over. Don’t worry, online technical support

also works.

3) One-year warranty , lifelong maintenance and spare parts supply service

Q6: What payment term do you accept?

A: Usually we accept the payment by T/T. Alibaba online trade assurance order will be OK, too.