Medical Mold

OK-Medical Are engaged in design and manufacture precision injection molds, typically with rich experience for medical devices.

In past 15 years, we have made and exported thousands of molds to over 30 countries around the world. Those molds cover different fields, including Infusion and Transfusion, Syringes, Hemodialysis, Respiratory, surgical instruments and Diagnostic equipment etc.

In addition to mold development, we also offer Plastic Injection Molding in ISO Class 8 clean room environment. The OEM molding is typically for plastic parts of Class III medical devices, such as Catheter/ Delivery System components.

Besides, we also can supply some common medical components like luer lock connectors, injection sites, I. V. Spike, clamp. Needless free connector, one way check valve, hemodialysis parts, catheter connector, urine bag components etc

Adhering to the tenet "Quality First, Customer Focus", we devote to providing optimal solutions of tooling and molding for medical devices industries.

|

| Test tube mold;Three colors medicine cup mould;Urine/Faeces collection cup mold;Dressing change Tray/Pincers mould |

|

| Petri dish mold;black mold in petri dish;petri dish mold test;petri dish mould |

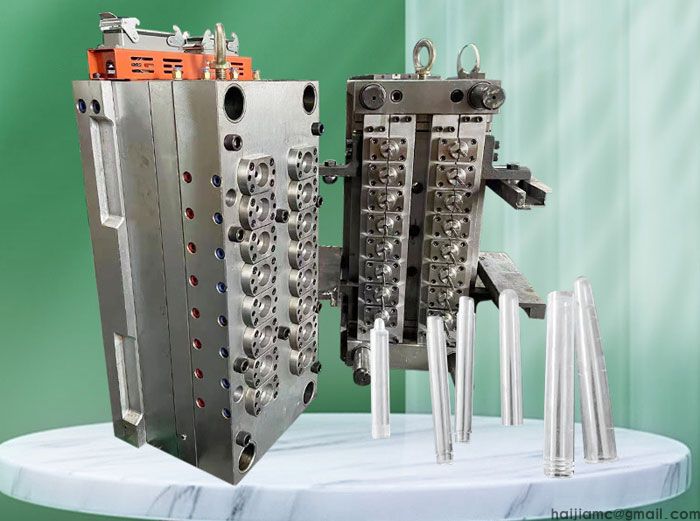

Mold Specifications:

| Description | Plastic injection mold for SYRINGE |

| Part Material | PP |

| Cavity number | 32/48..(optional) |

| Runner | Hot runner or cold runner |

| Core & cavity material | S136, 1.2083 stainless steel |

| Mould Standard | MISUMI, DME,CUMSA,HASCO |

| Mould life | Long mold life |

| Available format | .stp/.pdf/.x-t/.step./.dwg/.dxf/.igs/.prt/.stl/.sldprt |

Below is the general information and policy for our OEM/ODM plastic injection mold:

| Detailed info for mould steel | ||

| Mould material | Hardness | Mould life |

| P20 | HRC 28-33 | >300,000 shots |

| 718 | HRC 33-36 | >500,000 shots |

| H13 | HRC >43 | >800,000 shots |

| 2344 | HRC >48 | >800,000 shots |

| S136 | HRC 48-52 | >1,000,000 shots |

Our Capabilities:

1.Engineering design -plastic part design

-mold design

-flow analysis

-CAD/CAM

Our sophisticated designing team with decades of experience can provide the most appropriate design and manufacturing option for your product, ensure your product is put into production quickly and efficiently.

2. Mold build -prototyping

-pilot mold and tests

-production mold

-mold for export

-complex mold solution

All our tools are built right here in our own facility. Our modern, fully equipped tool shop is capable of producing tools to the highest SPI standard. We also have a team of full-time toolmakers who are capable of taking your tooling from concept to finished mold.

|  |  |  |

|  |  |  |

3.Custom plastic molding -ISO class 8 clean room

-ISO13485 management

-high and low volume running

-medical masterbatch

4.Post molding services -assembly

-printing

-packaging

-sterilization

Our Strengths:

Rich experience in medical products, design and develop molds against ISO standard

Good quality from a small spare part to a whole mold tooling

In-House Tooling Workshop make sure on time delivery

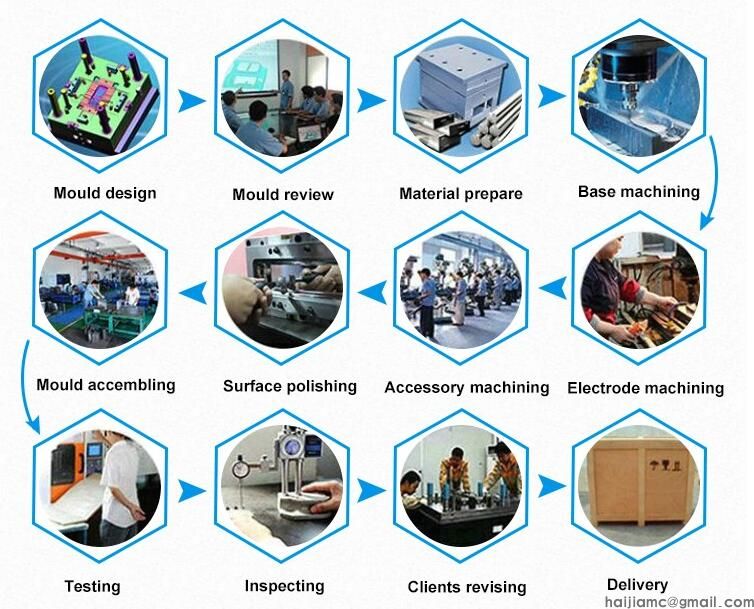

Working Process:

I. Order Confirmation and Advance Payment

II. Make DFM report, Mold Design 2D, 3D send you for approval

III. Order material, make the time schedule; weekly progress photos and process to you. Project engineer take charge of the manufacturing.

IV. Send T1 Mold Samples to you for evaluate, Part Inspection Report

V. T2 Mold trial, recheck the part dimensions

Mold Shipment:

1. Test the mold before shipment

2. Mold Inspection, take photos of mold

3. Spare parts, mold drawings packed along with mold in wood box

at Medical Exhibition:

Every year we attend international medical exhibitions for example CMEF,MEDICA, Arab Health, FIME etc.

FAQ About Plastic Mould Manufacturing:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection and Die casting mold.

Sometimes we also make stamping molds according to our customer's requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, We can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat_treatment /nitriding for the inejction mold plastic?

A5: Yes, As plastic mold fatory, we have long_term cooperated subsidiary factories that do those processes.They are professional and well reputed in our local market.

Q6: How long is the lead-time for a ?plastic injection mold?

A6: It all depends on the mold's size and complexity.Normally, the lead time is 25_45 days.If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by client.

Q8: How do you pack the china plastic moulds?

A8: We pack the plastic moulds with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any

any movement.