Eye protector glasses safety glasses medical goggle making machine

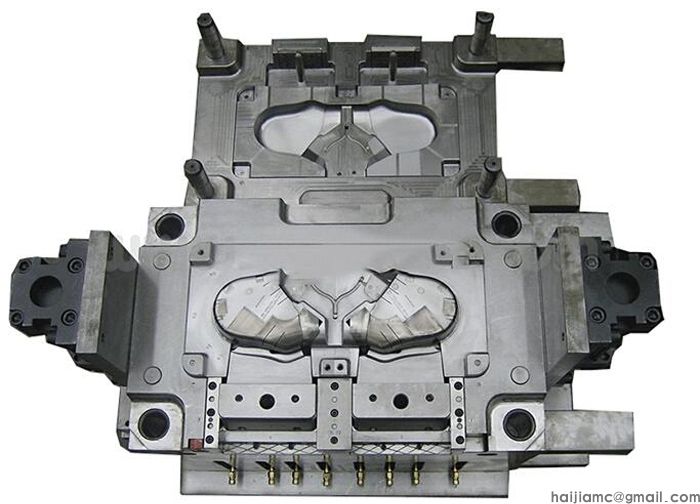

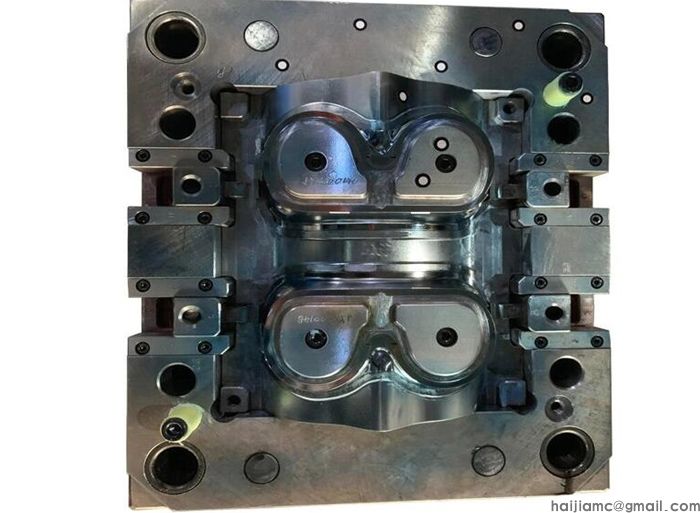

Goggle Mould specification:

| Item | Description |

| 1.Mould material | P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 |

| 2.Hardness of steel | vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 |

| 3.Inserts / Slider steel | H13 (DIN.1.2344),tempered with HRC46-50 |

| 4.Mould spare parts | H13 (Din 1.2344),tempered with HRC40-45,nitrited with HRC60-62 |

| 5.Mould base | LKM,HASCO |

| 6.Mould cavity | Single / Multi |

| 7.Runner system | Hot / Cold |

| 8.CAD centre for data formats | IGES,X_T,STP & DWG,etc |

| 9.Plastic material | ABS,PC,PE,PP,PS. |

| 10.Mould life | more than 1,000,000 shots |

| 11.Delivery time | 4-8 weeks |

| 12.Terms of payment | T/T, Paypal, Western Union and so on |

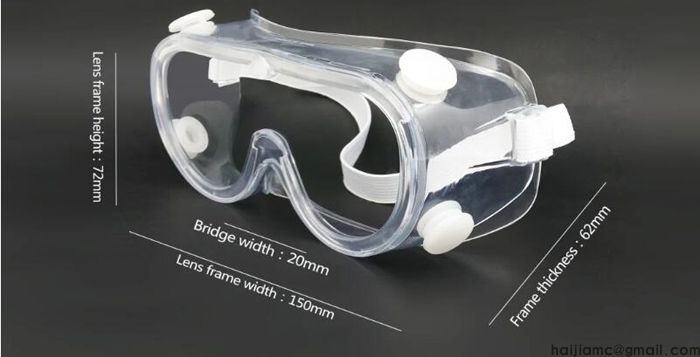

| Product | CE EN166 & ANSI Z87.1+ PC Material Anti-scratch Clear Industrial Eyewear Protective Safety Glasses goggles |

| Model Number | HJF2022 |

| Size | Adjustable elastic strap, adjusting for a better fitting |

| Material | Polycarbonate Lens with PVC Frame |

| Certification | CE EN166 ANSI Z87.1 AUS1337.1 |

| Lens | Anti-scratch, Anti-fog, Anti-UV available |

| Advantage | 1. Comfortable, ergonomically designed full vision goggle with unrestricted side visibility provided by 180 panorama lens 2. Indirect ventilation, soft and flexible PVC frame 3. High impact resistance Polycarbonate lens 4. Soft face and nose cushioning enables totally airtight and pressure-free fit 5. Easy headband adjustment |

FAQ About Plastic Mould Manufacturing:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection and Die casting mold.

Sometimes we also make stamping molds according to our customer's requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, We can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat_treatment /nitriding for the inejction mold plastic?

A5: Yes, As plastic mold fatory, we have long_term cooperated subsidiary factories that do those processes.They are professional and well reputed in our local market.

Q6: How long is the lead-time for a ?plastic injection mold?

A6: It all depends on the mold's size and complexity.Normally, the lead time is 25_45 days.If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by client.

Q8: How do you pack the china plastic moulds?

A8: We pack the plastic moulds with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any

any movement.

FAQ About Molded Products:

Q9: How many injection plastic mouldings machines do you have?

A9: We have 40 sets of ?plastic Injection Mouldings machines.

Q10: what is the minimum & maximum unit weight and size your machines can produce?

A10: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q11: What kind of plastic materials you usually use?

A11: We are specialized in producing plastic products with the following materials:

PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

FAQ About Worldwide Delivery

Q12: Can you deliver the plastic moulds or plastic products to our factory?

A12: Yes, We have cooperated with many international logistics companies for years.

And we have full experience to manage the delivery directly to the client's factory or

appointed warehouse.