Injection molding machines

Always the better choice for your requirements

As one of Chinese top leading plastic injection molding machine manufacturers.

From 10 to 3,000 ton clamp capacities, Haijiang offers you the widest range of injection molding machines. Choose from PET preform, servo or hydraulic machines with a full range of plastics processing technologies, including injection blow, multi-component and co-injection.We will always be your dedicated partner,giving you the best injection molding machines and the most efficient services.

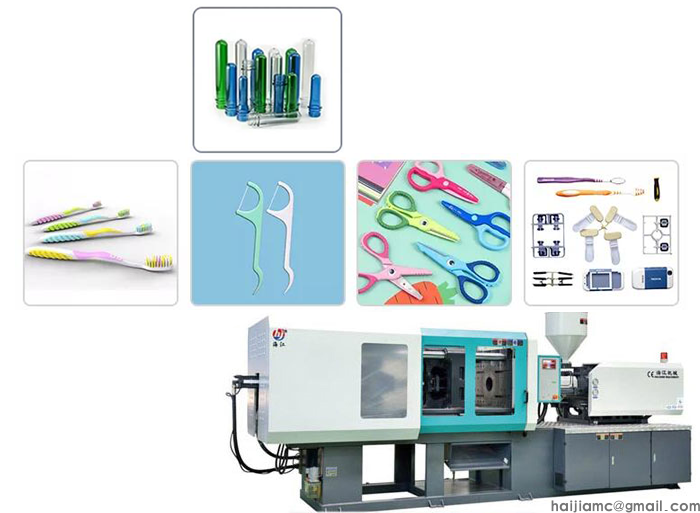

Plastic injection molding machine for sale & services:

1.PET preform injection molding machine(100 ~ 780 tons clamping forces)

2.High-speed/Close-Loop Hybrid injection molding machine (50~1000 Tons clamping forces)

3.Two Platen injection molding machine (1400 ~2000 tons clamping forces)

4.Two color injection molding machine (double shot/ double color plastic injection moulding machine)

5.LSR (silicone) injection molding machine (100 ~400 tons clamping forces)

6.Hydraulic injection molding machine (50 ~ 3000 tons clamping force)

7.Energy saving (servo) injection molding machine (50 tons to 3000 tons clamping forces)

8.Vertical injection molding machine ( Benchtop plastic)

9.Thin wall injection molding machine (machine to make plastic containers )

10.PVC pipe injection molding machine ( 180 ~650 tons clamping forces+fitting mold)

11.Plastic cap injection molding machine (140 ~400 tons clamping forces)

12.All electric (micro low pressure) small desktop plastic injection molding machine for sale

13.BMC injection molding machine (140 ~530 tons clamping forces)

14.Plastic shoes injection molding machine

15.Automatiive plastic injection moulder (automotive injection molding)

16.Plastic shoes injection molding machine (180 ~530 tons clamping force)

17.Manual injection molding machine (50 Tons clamping force)

18.BMC/Bakelite injection molding machine (100 ~580 tons clamping forces)

19.Medical injection molding machine(require medical injection moulding cleanroom)

20.PET injection blow molding machine

21.If you need cheap machine,we can offer used injection moulding machine too.

In order to provide products with highest quality to our customers,we put lots of effort to this mission.Our R & D department not only devoted to devoted to develop new products.

Haijiang IMM botains a well reputation for this machine's high quality and excellent functions.The HAIJIANG world marketing and servicing network rapidly and efficiently support the customers'needs.Wherever your business venture is,Haijiang will be always with you and provide you the most prefoessional service.

I. Series PET injection moulding machine

If you are going to to add a new preform production line or start a new business in the PET preform sector, Do you know how to choose the right PET preform equipment model for your project?

You need to learn some details about the PET preforms Information such as preform weight, the neck diameter of preform, daily capacity which you want to produce. Based on this information, plastic molding machine manufacturer will recommend suitable mold cavities and the model of the machine.

Important points for choosing the right plastic moulding machine

A.Sufficient clamping force

B.Pay attention to the actual injection volume and screw diameter of the machine

C.The tie-bar distance, mold height and minimum molds for plastic injection size should be considered

According to the size of the plastic injection molds and preform, judge whether the opening stroke and ejection stroke are sufficient for product demoulding

II.series High speed injection molding machine

It is a kinds of fast machinery,can make round plastic containers,

Designed for the demanding application technology. HJF-S includes upgraded installed power package and controller system allowing injection speeds up to 200 mm/s which is needed in thin wall components. The multi-pump configuration allows it to perform complicated synchronous motion to reduce the cycle time.

· German gear pump paired with permanent magnet servo motor deliver the efficiency and accuracy

· High installed power well suited for demanding injection molding processes

· Multi-pump configuration allows high injection speed up to 200 mm/s. It also allows synchronous motion to reduce the cycle time

· High-end controller system, master the machine process in detail. Keep track with the process and production data in order

· plastic moulded platen and sturdy toggle clamp system designed by advanced FEA engineering design aided system to assure minimum deflection and maximum strength possible

· Excellent kinetic motion characteristics result in good dry cycle performance and steady movement

· User-friendly features include push-pull ejector with quick coupler connection

· Screw and barrel built with high-quality import alloy steel, options for special material and bimetallic screw and barrel are available

· Clamping force: 50 - 1000 Tons

III.Two Platen injection molding machine

A versatile and efficient injection molding equipment for large parts

The compact Haijiang two-platen injection molding machinery will let you enjoy the freedom of small footprint, multi-functional process capability, tons of application-orientated add-on modules which sophisticated processors are seeking.

IV.Two or multi-color color injection molding machine

It is use for For multi-color or multi-material plastic parts,Haijiang

injection molding machines can produce plastic parts combined with 1-3 color/materials which are commonly found in automotive lighting, internal trim, electrical appliances, household appliances and houseware. It integrates the servo energy saving concept and control algorithm.

V.LSR (silicone) injection molding machine

With the continuous advancement in the industries worldwide, the requirements for the industrial and consumer products are on the rise, demanding product to be environmental friendly, impact resistant, heat resistant, and recyclable. As a result, the injection molding technology has also be upgraded. The evolution of technology has taken the injection molding process from the traditional thermoplastic to the thermoset plastic today, where the thermoset injection molding process is divided further into hard plastic and soft plastic. Hard plastic is also known as bakelite and uses BMC injection process while soft plastic refers to liquid silicone injection process.

Liquid silicone resin (LSR) is characterized by good liquidity, low viscosity, fast solidification, and higher thermal expansion

coefficient. Liquid silicone injection molding uses a two-part material delivery system which consists of an A component and a B component with a 1:1 ratio controlled by a quantitative device. After feeding the materials fully blended through the static blender into the barrel, they will be injected for molding production, heated in the mold for vulcanization and solidification.

Haijiang LSR machine is a dedicated liquid silicone injection molding machine that integrates the professional LSR injection unit with the HJF platform. It offers high precision, stability, reliability, and repetition accuracy to meet customer needs with improved product yield.

VI.Hydraulic injection molding machine

With years of experience in manufacturing injection molding machines, Haijiang Injection Molding Machine brand keeps up with market demand. Adopting an advanced design concept, using a high-precision controller and energy-efficient variable pump, launched high-precision Series HJF injection molding machine into the market. Haijiang IMM is customer oriented and based on a modular-design engineering, provides reliable advice and the perfect solution for injection projects. We offer qualified service and provide injection molding machine in all different spheres of industry, including: food packaging industry, household products industry, household appliances industry, electronic industry, auto industry, pipe fittings, toys, gifts, and other industries. The clamping force 50 – 3000 Tons.

VII.Energy saving (servo) injection molding machine

Our servo plastic mold injector offer energy efficiency, reliability, precision & product versatility Haijiang’s servo injection molding machines offers energy efficiency, reliability, precision, and product versatility. The reduced energy use reduces the heat load on the factory and reduces maintenance and operational costs over the life of the machine.

VIII.Thin wall injection molding machine for sale

high-speed production of applications such as thin-wall food packaging, closures for beverages, cartridges, plant pots and buckets. Taking a “best of both worlds” approach to injection molding, the hybrid series combines speed and performance with:

· Ultra-high-speed injection via hydraulic accumulator and servo-valve

· Energy-efficient electric screw drive for maximum plasticizing capacity and melt homogeneity, and a clamping unit with AC servo drive and hydrostatic transmission for fast, energy-efficient mold open/close.good machine to make plastic containers.

IX.All-Electric Injection Molding Machines

Haijiang manufactures one size all-electric injection molding machines 10 U.S. tons,it is desktop injection molding machine. require a very small injection mould.

Small low pressure injection molding machine feature:

Machine Weight: 120kgs

Screw Diameter: 16

Injection Unit Motor Torque: 12N*m

Clamping Unit Motor: 8N*m

Maximum shot Weight: 10grams

Maximum Clamping Force: 20KN

Temperature Control Range: 50C-350C

Heating Connect Point: 4 heating band

Mold Opening Stroke: 135mm (not included mold)

Maximum Mold Size: 150mm*150mm

Injection Speed: 12second (5grams PP material )

Control System: 5 Inch touch screen

Power: Single Phase 220V/1kw

X.Vertical plastic injection moulding machines

Haijiang machines are widely applied in the field of injection overmolding, multi-colors injection molding, multi-components injection molding, high-precision injection molding, in mold labeling injection molding,thermosetting injection molding,liquid silicone injection molding,insert injection molding and rubber injection molding.

Haijiang Services

When choosing an device plastic injection molding, the customer's requirements are the most relevant. Haijiang therefore classifies the machines based on the following customer requests:

1.Fastest availability

The new plastic injection molding machine is quickly at your production site.

2.Maximum flexibility

The injection mold machines can be customized to meet your specific needs.

3.Highest performance

The plastic injection machine is designed for lowest cycle time and highest precision

The use of high-quality plastic components is unlimited. The requirements of the parts are versatile.injection moulding products different shapes.

4.Enough plastic injection moulding machine spare parts

No matter what you produce:

Caps and closures, food packaging, pails or thin wall containers,

Automotive components for micro parts, car body, lighting, or lightweight construction,

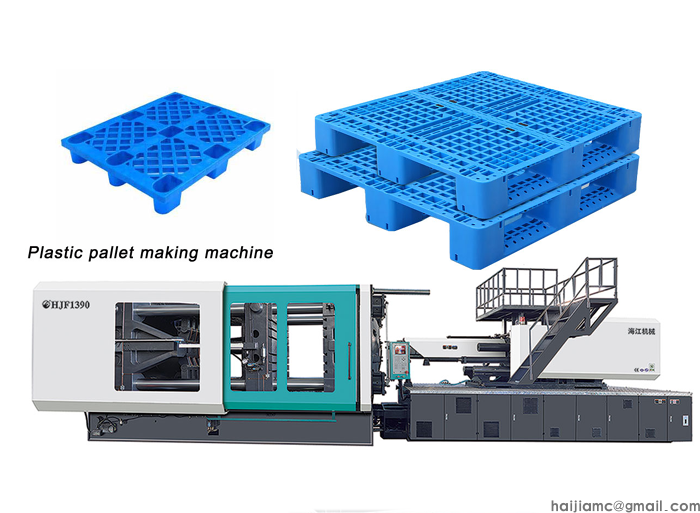

Products for daily life such as household appliances, toys or furniture, tanks or pallets for the logistics industry

Pharmaceutical and medical technology products such as syringes, pipettes, or other products with high levels of cleanliness,

Various injection molded parts for electrical components, electronic products and more.large scale plastic molding.

We offer you the right turnkey solution for maximum productivity.offer injection molding training for your workers too.