Haijiang make a plastic injection molding machine more energy efficient from below ways:

- Optimize the injection molding process: By optimizing the process parameters, you can reduce the energy consumption of the injection molding machine. This includes optimizing the melt temperature, injection pressure, and mold temperature.

- Use energy-efficient motors: Using energy-efficient motors can help reduce the energy consumption of the injection molding machine.

- Install energy-efficient lighting: Replacing traditional lighting with energy-efficient LED lighting can help reduce energy consumption.

Use energy-efficient heating systems: Injection molding machines use a lot of heat, so it's important to use energy-efficient heating systems to reduce energy consumption.

- Use energy-efficient cooling systems: Plastic Injection molding machines also use a lot of cooling, so it's important to use energy-efficient cooling systems to reduce energy consumption.

- Use an energy-efficient power supply: An energy-efficient power supply can help reduce the energy consumption of the injection molding machine.

- Use energy-efficient controls: Energy-efficient controls can help optimize the energy consumption of the plastic injection molding machine.

- Use an energy management system: An energy management system can help optimize the energy consumption of the plastic injection molding machine and the entire production line.

Conduct regular energy audits: Regular energy audits can help identify opportunities for energy savings and help implement energy-saving measures.

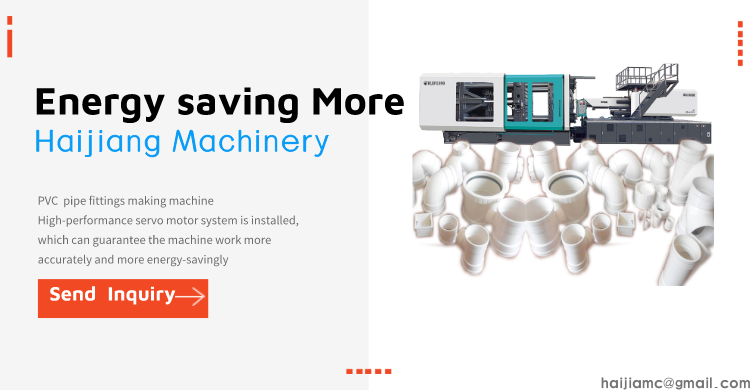

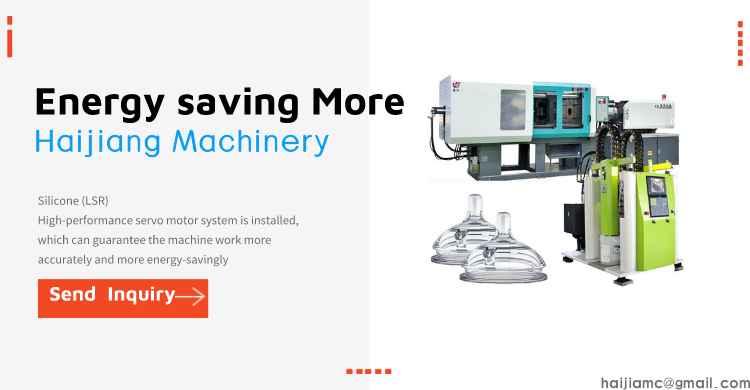

Servo injection molding machines, also known as servo motor plastic injection molding machines, are injection molding machines that use servo motors to drive the injection mechanism. They are typically more energy efficient, quieter, and more precise than hydraulic injection molding machines, which use hydraulic pumps to drive the injection mechanism.

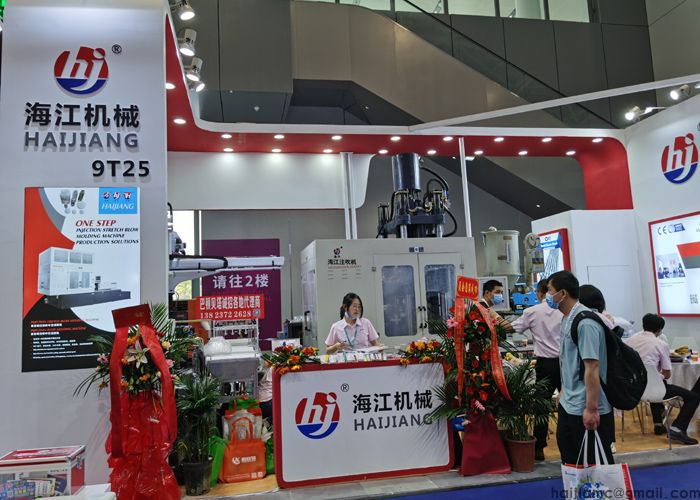

Haijiang Plastic injection molding machine for sale & services:

1.PET preform injection molding machine(100 ~ 780 tons clamping forces)

2.High-speed/Close-Loop Hybrid injection molding machine (50~1000 Tons clamping forces)

3.Two Platen injection molding machine (1400 ~2000 tons clamping forces)

4.Two color injection molding machine (double shot/ double color plastic injection moulding machine)

5.LSR (silicone) injection molding machine (100 ~400 tons clamping forces)

6.Hydraulic injection molding machine (50 ~ 3000 tons clamping force)

7.Energy saving (servo) injection molding machine (50 tons to 3000 tons clamping forces)

8.Vertical injection molding machine ( Benchtop plastic)

9.Thin wall injection molding machine (machine to make plastic containers )

10.PVC pipe injection molding machine ( 180 ~650 tons clamping forces+fitting mold)

11.Plastic cap injection molding machine (140 ~400 tons clamping forces)

12.All electric (micro low pressure) small desktop plastic injection molding machine for sale

13.BMC injection molding machine (140 ~530 tons clamping forces)

14.Plastic shoes injection molding machine

15.Automatiive plastic injection moulder (automotive injection molding)

16.Plastic shoes injection molding machine (180 ~530 tons clamping force)

17.Manual injection molding machine (50 Tons clamping force)

18.BMC/Bakelite injection molding machine (100 ~580 tons clamping forces)

19.Medical injection molding machine(require medical injection moulding cleanroom)

20.PET injection blow molding machine

21.If you need cheap machine,we can offer used injection moulding machine too.

If you want to know plastic injection molding machine price,please feel freely contact us.

- Lower energy costs: An energy-saving injection molding machine uses less energy to produce the same number of parts as a conventional machine, which can result in significant cost savings.

- Reduced carbon footprint: Using an energy-saving injection molding machine can help reduce a company's carbon footprint by using less energy and, therefore, producing fewer greenhouse gas emissions.

- Increased efficiency: Energy-saving injection molding machines often have faster cycle times and better temperature control, which can lead to increased efficiency and productivity.

- Improved product quality: Energy-saving injection molding machines may also have better control over the injection process, leading to improved product quality.

- Increased competitiveness: By using an energy-saving injection molding machine, a company can reduce its production costs and become more competitive in the market.

- Energy efficiency: Servo motors use only the energy needed to complete the specific task, whereas hydraulic pumps use a constant flow of energy, even when the machine is idle. This can lead to significant energy savings, especially in facilities that run multiple injection molding machines.

Quiet operation: Servo motors operate at a lower volume than hydraulic pumps, which can be a significant advantage in facilities where noise levels need to be kept low.

- Improved precision: Servo motors offer precise control over the injection process, which can result in more consistent and higher quality parts.

- Enhanced productivity: Servo motors can respond more quickly to changes in process conditions, which can result in faster cycle times and increased productivity.

Increased flexibility: Servo injection molding machines can be easily programmed to produce a wide range of parts, making them more versatile than hydraulic injection molding machines.

Overall, servo injection molding machines offer a number of advantages over hydraulic injection molding machines, including energy efficiency, quiet operation, improved precision, enhanced productivity, and increased flexibility.

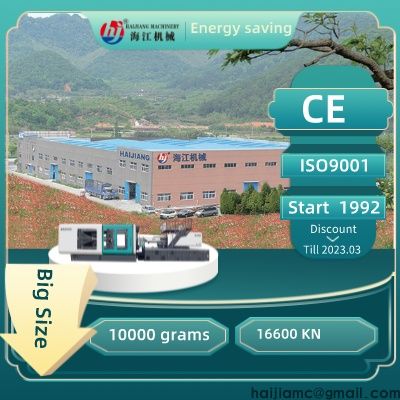

Haijiang injection molding machine-Energy saving.It is the best choice for you.