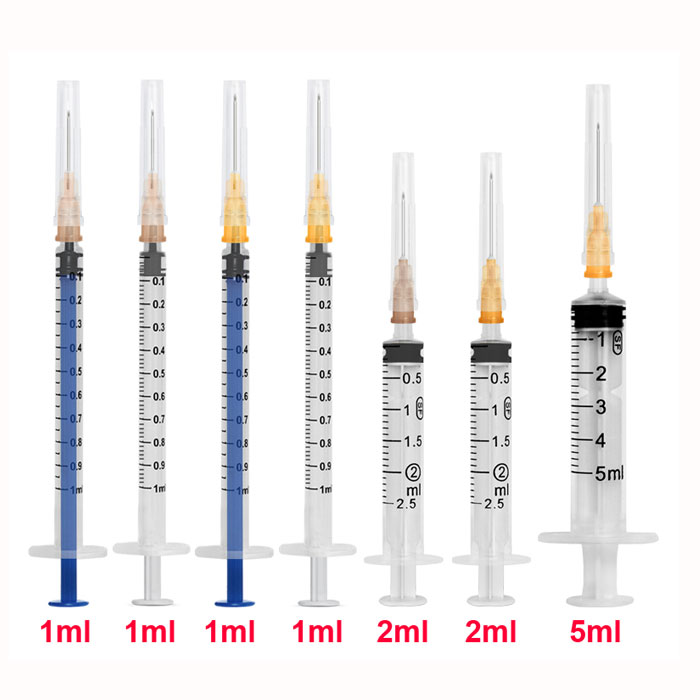

There are so many different syringe on market. luer lock syringe;luer slip syringe,insulin syringe,3 ml syringe,5ml syringe. all of them require syringe mould.

medical micro molding company. medical silicone injection molding not used on syringe. IV insusion set have a silicone connector.

As a syringe mould manufacturers,we care about the mould quality much. must offer quality molds to customer. on the syringe,there is a rubber stopper. so factory will do medical rubber molding. but someone buy rubber stopper from market.Tool syringe not much cost. only depend on clients's wish.

The price of mould always is a topic that people concerned .Actually the quality of syringe mould should be thought first before the price for it's the basic condition of products. It's worthwhile for having a relatively high price mould but can provide you the best quality products with long service time. That's what I say the best mould .

The quality : syringe Mold's quality is up to the level of product knowledge. Using the right mould materials, right processing technology and the right mold structure can make the best mold. Only professional medical consumables mold manufacturers an do this for you .We can say that in the same period, the same price, our quality is best.

After Sale: One year free repair, life-long maintenance. Mould from our company, free maintenance would

always be provided to the customer to remove the trouble back at home.

Syringe Mold service life: There have soft mold, hard mold and super hard mold in injection mold industry. In theory, soft mold life is expected to be five hundred thousand times, hard mold for one million times, super hard mold for more than one million times. But it turns out to be the theoretical value for the mold maintenance by user make a great difference of mold life. But we can ensure you in the terms of mould material, processing technology and mold hardness processing , to make the mold most times use in normal use.

Syringe Mold Specifications:

| Description | Plastic injection mold for SYRINGE |

| Part Material | PP |

| Cavity number | 32/48..(optional) |

| Runner | Hot runner or cold runner |

| Core & cavity material | S136, 1.2083 stainless steel |

| Mould Standard | MISUMI, DME,CUMSA,HASCO |

| Mould life | Long mold life |

| Available format | .stp/.pdf/.x-t/.step./.dwg/.dxf/.igs/.prt/.stl/.sldprt |